Scaffold Erection in Confined Space

Introduction

As part of the silo reinforcement project, Talos Group had to access the silo walls from the ground to top of 6.85m diameter, 25m high cement silos. The reinforcement process required technicians and workers to be working close to the surface of the silo for a prolonged time. Therefore, the most suitable was approach was to erect scaffolding tower with a series of platforms inside the silo.

Work Performed

-

Silo Cleaning

-

Breaking of silo base/floor pyramids

-

Erection and dismantling of 25m scaffolding tower inside the silo

Scope

A cement manufacturing company required a full silo internal reinforcement as a way to increase safety and the general life span of 4 out of 6 silos. This case study highlights one of the scaffolding process as one of the overall project milestones. Talos made use of the easily adaptable Layher All-round scaffolding for this task.

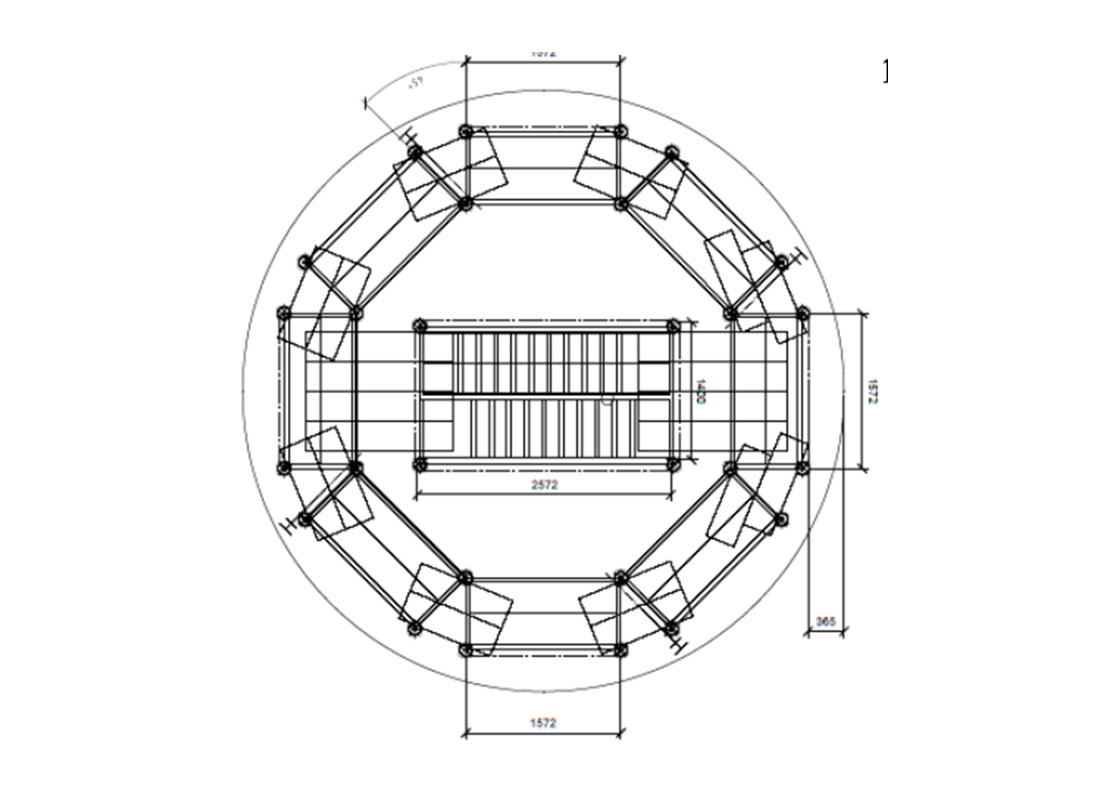

Figure 1: Scaffolding tower model done outside the silo

Access

Most of the scaffolding components were small enough to fit through the side access doors of the silo once the silo cleaning was completed. The silo cleaning process was carried out with Talos Group’ skilled rope access technicians.

The larger rigid sections of the scaffolding like aluminum staircase and handrails were hoisted on to the roof of the silo with an electric winch where there was a larger access man-hole and subsequently lowered into the silo with the winch.

Figure 2: Access method used during the project – side access door

Solution

According to the engineering design, the interior walls of the silos had to be reinforced, and as mentioned, 25m scaffolding towers were erected inside the silos. These towers provided access for the steel fixing and shotcrete technicians to perform their respective tasks.

The geometric design of the silo had pyramids on the base of the silo that facilities the flow of material. However, this base created a new challenge for the stability of the scaffolding tower. Talos Group engineers found it best to demolish the silo base pyramids and allow the scaffolding to start on a flat and more secure floor. Our qualified scaffolding technicians erected the Layher All-round scaffold which allows for the curved silo wall profile and ensures that the technicians will reach the walls of the silos safely. Our NEBOSH qualified Health and Safety Officer, together with the clients’ independent scaffolding inspector were called in before the scaffolding tower was in use.

Part of desk study done by the Talos Group engineers and Health and Safety team included the calculations of the dead load and live load of the scaffolding tower on to the existing silo foundation and the adequacy of the bracing required during work (steel fixing and shotcrete).

Basic safety rules adopted by Talos Group for works in a Confined Space included; rescue plan, adequate lighting, proper ventilation (with continuous oxygen content checks), no lone working and a hole watchers present.

Figure 3: Scaffolding tower layout – Desk study

Figure 4: Scaffolding tower in use during steel fixing of heights up to 25m

Figure 5: Scaffolding tower in use during shotcrete inside the silo

Conclusion

The silo reinforcement was completed successfully. The use of the scaffolding tower inside the silo allowed for the safe working environment considering that the work had to be done in a confined space. This method was also advantageous for the technical aspect of the project as the technicians worked better on the platforms. Talos Group Construction has all the necessary resources and expertise to ensure efficiency in your production cycles.