Roof Cleaning

Introduction

Talos General Construction, under Talos Group, was engaged by a cement plant to clean its roof for a Cement Mill roof after a collapse. The unexpected partial roof collapse of the cement mill prompted the immediate Roof Cleaning.

Work Performed

- Structural inspection of the roof and desk study

- Derive methodology

- Clearing of waste material

Scope

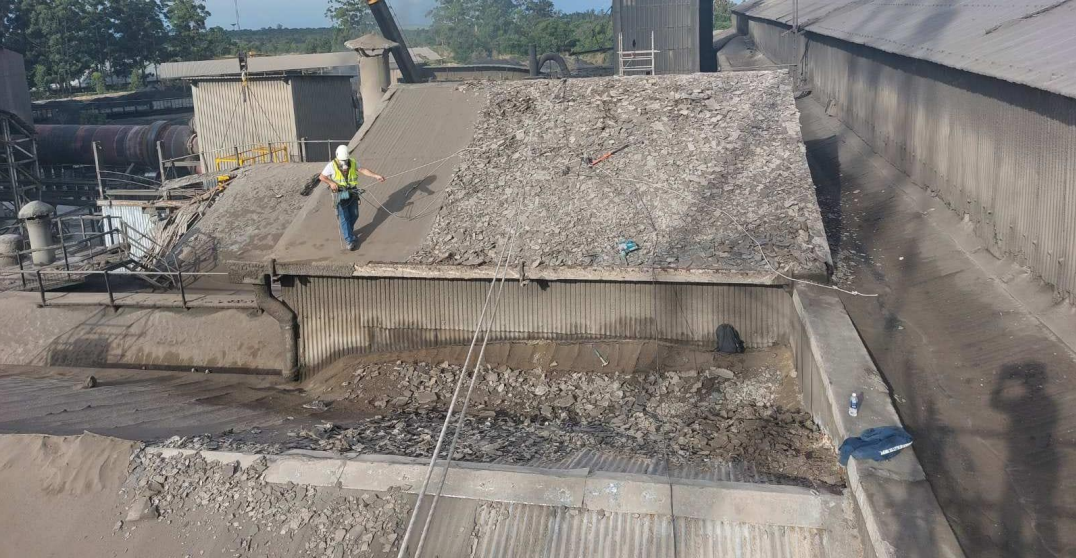

A cement mill roof collapse of a cement manufacturing company prompted an immediate roof cleaning exercise. Apart from the engagement of Talos Group to attend to the roof collapse, they were also required to clean the roof to reduce the dead load from the caked cement. A drone inspection was the

best way to approach the structure for difficult access and potential safety hazards. Photographic evidence from the drone showed the risk level and the amount of material on the roof.

The information gathered brought about the methodology of cleaning the roof with rope access technicians, as this was the safest way to work on the roof.

Figure 1: Condition of the roof and the collapsed roof section view from the drone

Access

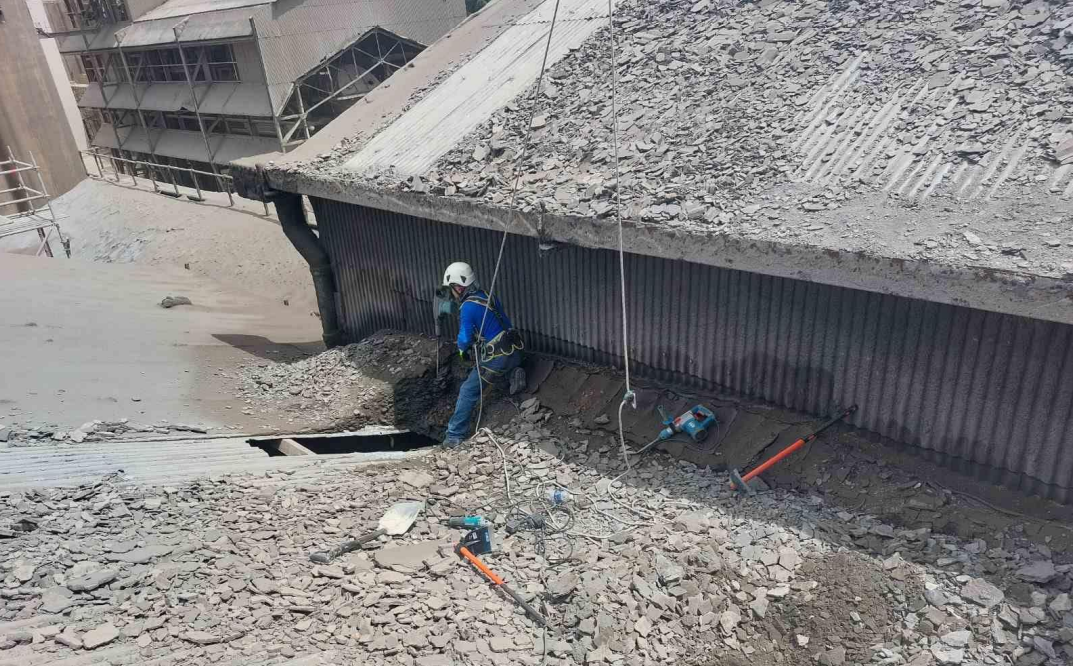

Due to the risk level, approaching the roof structure was deemed dangerous without a secured lifeline.

The drone enabled the rope access techniciansto come up with strategies on areas to work on. Scaffolding towers were erected on opposite sides of the building and lifelines were attached across.

Figure 2: Method used to access the roof and removal of debris

Figure 3: Scaffolding towers with life-line ropes

Solution

Talos Group first demolished the collapsed roof section and separated it from the remaining roof. The collapse of the roof was mainly due to additional dead load on the roof from caked cement dust and suspected modifications made on the roof truss during the installation of equipment.

The first team removed the rubble on the collapsed section with the use of two mobile cranes, one with a man-basket and the other one for hoisting metal roof sections. The rope access technicians were responsible for the cleaning of the remaining section of the roof. The roof had accumulated cement and

clinker dust over several years, which hardened creating a thickness between 20 to 500mm of hardened cement and clinker dust.

Using the scaffolding tower and lifeline, the technicians approached the roof. The hardened cement on the roof had to the removed using electric rotary and pneumatic hammers. Shovels and hoes were used to scrap off the rubble to the ground for disposal. A high-pressure water jet machine was used to wash

off excess waste material and all the damaged roof sheets had to be replaced.

Figure 4: Roof cleaning in progress

Figure 5: Debris clearing in progress

Figure 6: Roof debris cleaning

Results

The roof cleaning of the cement mill was done safely and successfully. The process of removing the unexpected dead load on the roof reduced the risk of roof collapse. It is important to periodically clean roofs at a cement factory for any dust settlement can compromise the structural integrity that can

subsequently result in roof collapse. Talos General Construction has all the necessary resources and expertise to ensure efficiency in your production cycles.