Installation of Monitoring Instruments

Introduction

Infrastructure that is close to the end of its design life should be regularly inspected for any defects, cracks

or possible structural failure. These inspections or monitoring can be done periodically or continuously.

The latter can be made possible using a data logger supporting vibrating wire and geotechnical sensors.

Data loggers automatically monitor and record parameters, measure conditions, and analyze. This information can ensure that regular maintenance is carried out on important infrastructure.

Work Performed

- Installation of monitoring instruments

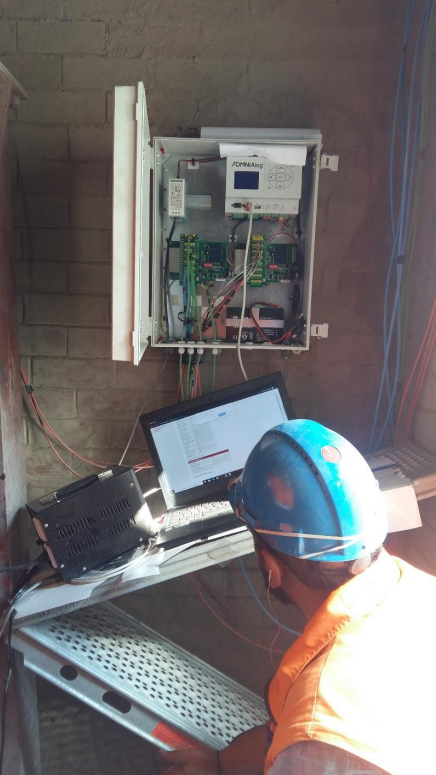

- Calibration and programming of software

Scope

Talos General Construction was engaged by a cement manufacturing company to rehabilitate its cement silos which were on the brink of collapsing. As part of the exercise, Talos had to monitor the behaviour of the silos as they work in and around them. The behaviour in question included settlement, tilting and cracking. The primary task wasto stabilize and reinforcement of the silos to increase the life span. Working

on the silos brought about the need to have an understanding of any possible behaviour and allow for an

emergency response

Figure 1: Installed crack meter and installed H-level

Figure 2: Sisgeo Tiltmeter before installation

Access

Talos engineers strategically installed three types of instruments on the silo. Access was dependent on the position recommended. Tilt meters and some of the crack meters had to be installed on the top of four silos, therefore, the technicians had to access them using a man-basket hoisted by a crane. H-level

instruments for settlement were installed underneath the silos, and this part of the silo was easily accessible from the ground

Figure 3: Access method to the top of the silo for installation of tiltmeters and crack meters

Solution

Talos Group engineers have extensive experience in installing, troubleshooting and configuring data loggers. The crew will safely access the silos and install them in strategic positions as recommended.

Tiltmeters were installed on top of four silos to monitor if there was any biaxial movement of the silos.

The following installation made was of the electronic crack meters, these were put on cracks which were considered dangerous during the silo operation and reinforcement process.

To monitor the differential settlement of the silos during stabilization, an h-level liquid level system was installed at the base. It consists of a

series of H-level gauges that are hydraulically connected to a reference tank positioned in a stable location. Each H-level gauge includes a high-resolution pressure sensor that monitors the head of liquid resulting from the difference

in elevation between the gauge and the reference tank.

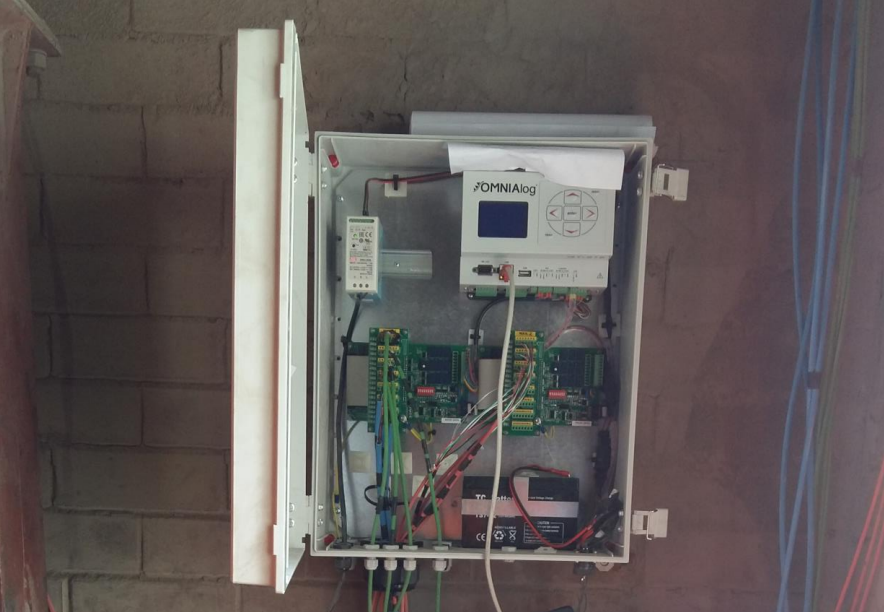

The H-Level system is available in both digital and analogue versions. The digital output allows fast and simple installation. With OMNIAlog data logger and digital gauges, you have the unique advantage of setting up the logging system just with one

click.

Figure 4: H-level liquid level system

Results

The installation of the monitoring equipment onto the silo was completed safely and successfully. Continuous monitoring of the silos was made possible.

For extra measure, an alarm system was installed in cases set parameters are

reached. This will be useful in case of immediate evacuation. Daily reports on the

behaviour will be available on the data logger.